Hot Melt Adhesives for the

FILTER Industry

Our filter assembly hot melt adhesives are designed to be use on most filter manufacturing and equipment . They are made to bond most substrates including – fiberglass, nylon, plastics, rubber, foam and difficult to bond coated paper substrates.

In the filter manufacturing industry, there are many applications where hot melt adhesives are used, because they are resistant to high and low temperatures and offer fast set times. That is the reason that they are widely used in the manufacture of filters.

Hot melt adhesives with fast set times are often the best choice when manufacturing air filters; because of the fast-running filter machines need a fast set time. Hot melt seals the filter frames, laminates the filter media and carefully closes the separators.

Polyamide based hot melt adhesives are also used for air filters in industrial or car ventilation systems that have to withstand high temperatures. These hot melts are highly chemical- and heat-resistant – and offer strong adhesion to papers and non-woven fabrics.

Household purifiers can effectively improve indoor air quality and reduce indoor air VOCs.

Our purification series products are divided into origami glue, welt glue, round cover glue and styrofoam glue.

Poseidon hot melt adhesive can achieve a good bonding effect on filter bonding, environmental protection, high-strength bonding, cold and heat resistance, aging resistance, excellent performance and stable quality, which can provide the perfect bond for various manufacturing solutions.

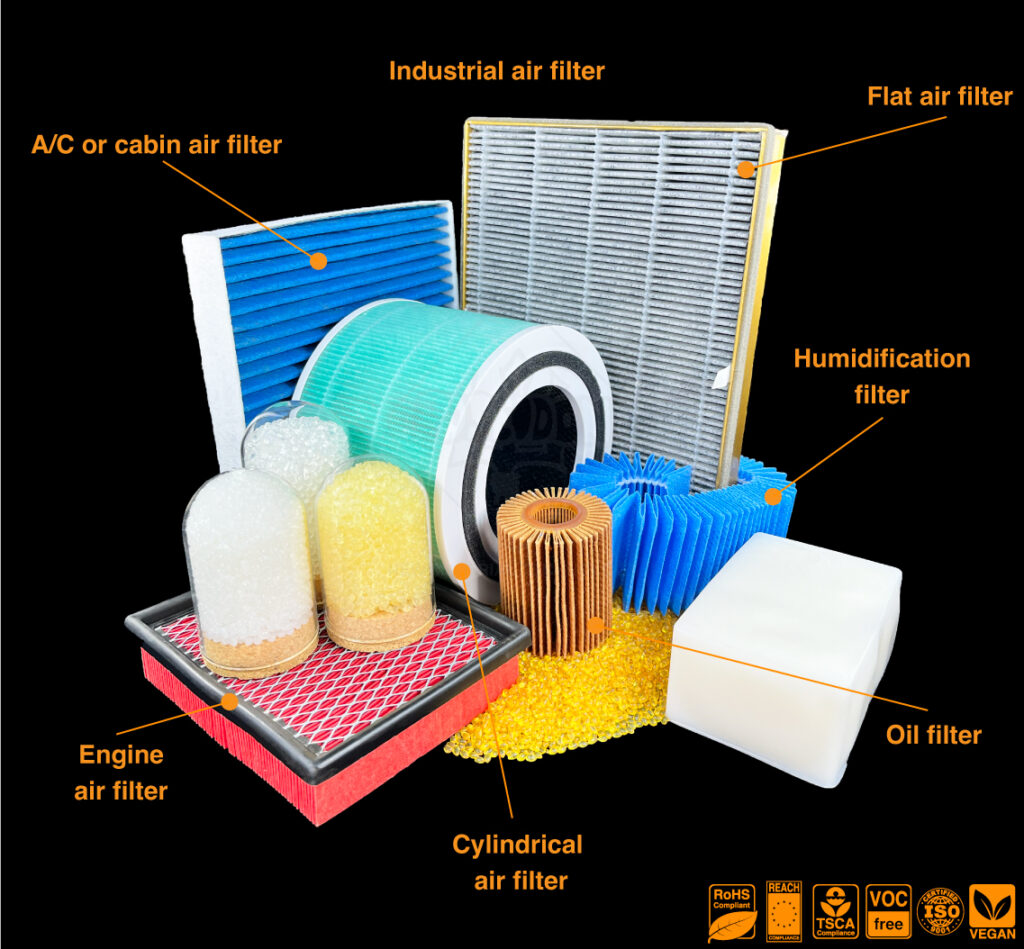

Automotive filtration is divided into air conditioning filtration, air filtration and oil filtration, which respectively play a role in reducing VOCs in the car and protecting the engine and auto parts.

Our series of products are divided into origami glue, welt glue, interior glue.

“Remember if you can’t find the right HMA for your company, we can always develop one according to your specifications.” Jacky Liu – GM